Indian Oil Corporation Limited (IOCL), a Maharatna PSU, places turnkey order for Waste Heat Recovery Boiler (WHRB) on Incinerator on ME Energy. M.E Energy vast experience in Thermal Engineering and their professional approach in executing custom built systems helped them to clear the stringent tendering process. The consultant for the project is Belgium based Tractebel Engineering, a global engineering consultancy company with more than 100 years of expertise in energy and infrastructure projects.

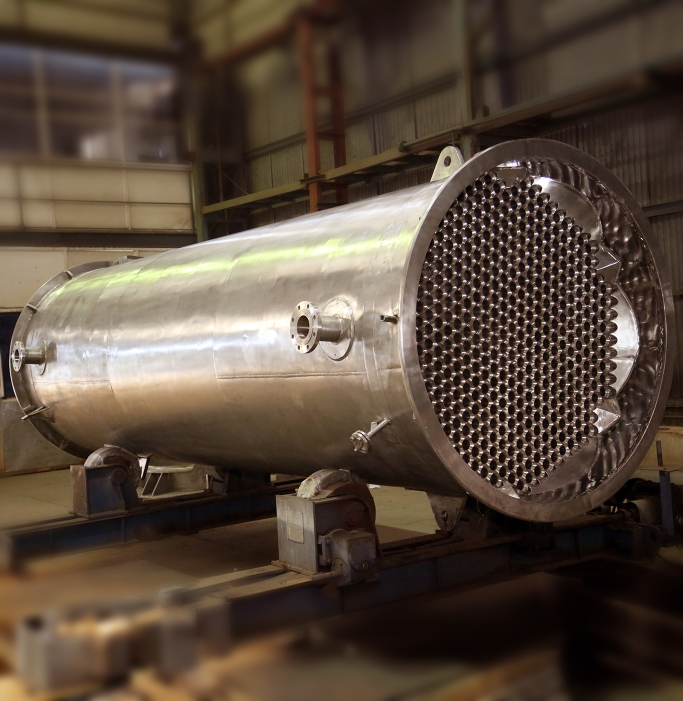

The existing Bitumen blowing Unit at Mathura refinery has two reactors running in parallel. The off gases generated from the reactors are burned in an incinerator. The air to the incinerator is provided by dedicated air blowers. The off gases are burned at a temperature of ~ 850 deg C. The off gases are cooled in the duct by injecting air and then the flue gases are released to the stack. The huge quantity of flue gas at a temperature of ~ 800 – 850 deg C has a huge potential to recover energy where the M.E Energy expertise comes into picture. The Waste Heat Recovery Boiler is vertical, water tube type construction with a Steam Generation capacity of 10.2 TPH at 13 Kg/cm2(g) at 260°C. The generated steam shall be used in refinery process application.

“M.E Energy has excellent solutions for Waste Heat Recovery in Oil & Gas, Petrochemicals, Fertilizers, Chemicals, Steel and Automobile Industries. Our past track records in last 17 years and Customer focus approach helped us to win this prestigious order from IOCL and we hope to achieve many more milestone in the near future” Mr. K. Vijay Kartha, Managing Director said.