M.E Energy Pvt. Ltd., a Pune based thermal engineering company has bagged a large export order to design, manufacture and supply 20 Boilers & Systems to generate 16 MW electricity using waste heat from Gas Engine Generators of a 200 MW power plant in Bangladesh. The order was won by offering superior technical solution against stiff competition from more than a dozen manufacturers from around the globe.

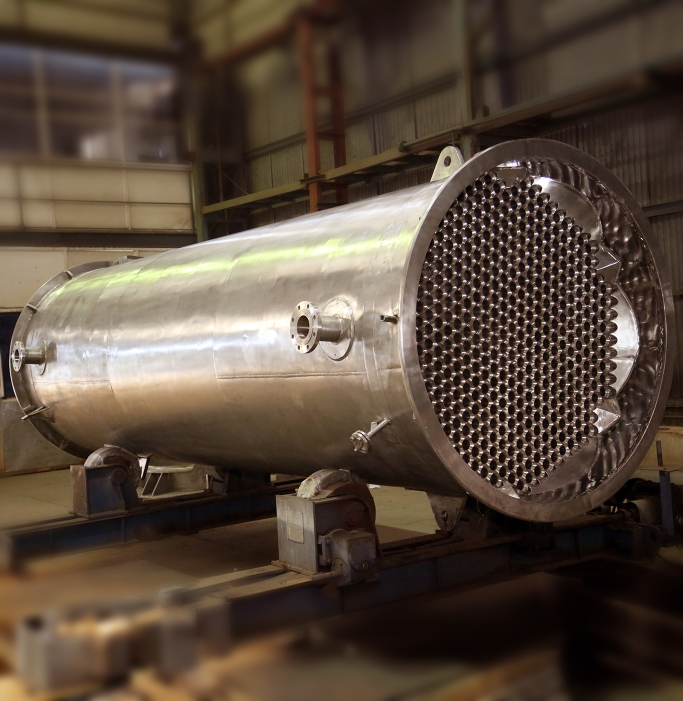

The Gas/ Fuel Oil fired engines used in the industry uses hardly 45% of the heat generated from the fuel and the balance goes out to the atmosphere as waste heat through the radiators and smoke. M.E Energy will design, manufacture and install Waste Heat Recovery Boilers to recover the waste heat from the smoke to produce steam. And this steam produced at zero fuel cost will be fed to a Steam Turbine to produce electric power. This is also called a combined cycle power plant.

Electricity generated by this project, which otherwise would have gone totally waste, can cater to the needs of more than 14,000 homes and the project will save energy equivalent of around 90,000 litres of fuel oil (Diesel or Furnace Oil) or around 220 Tonnes of Coal per day.

“This agreement reinforces the company’s commitment and its mission to consolidate and grow to become a world class technology driven compan y, providing customized solution in the field of energy savings.

Energy saving measures has been made compulsory for all the new power plants. Similar policy level interventions are the need of the hour for our country too, which is reeling under acute shortage of electricity.” Mr. K. Vijay Kartha, Managing Director said.

GM – Business Development – M.E Energy, Mr. Feroz Siddiqui added that the total investment for the project which will be completed in around 6 months is approximately 8 Million US Dollars and M.E Energy intends to focus on many such projects in the coming days.